The automation of industries has driven the evolution of components to be more productive, tough, and require less maintenance than ever. One such component is the solid state relays (SSR) which offer better performance and reliability than traditional electric system SSRs used in B2B infrastructures. Unlike older mechanical relays, SSRs have the advantage of a non contact switching system which further reduces accuracy and wear and increases the speed and life of the relay.

The purpose of this article is to explain solid state relays comprehensively, their construction, advantages, use cases, and considerations that B2B customers need to have before purchasing. Moreover, we show how OMCH has positioned itself as a reliable automation brand that provides SSR solutions suitable for industrial requirements.

What is a Solid State Relay?

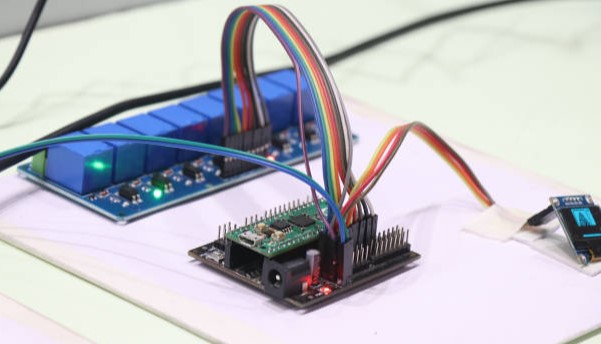

Definition of solid state relays can be described as a device that changes electricity flow or current using its original contacts using semiconductor parts instead of mechanical ones. The essential parts of an SSR usually consist of:

- Input (control) circuit: Receives input from the system controller (PLC, microcontroller, etc.) and integrates with other components.

- Trigger circuit: Turns on the switching device’s control circuit.

- Output circuit: Holds the load and does the switching using a triac, thyristor or a mosfet.

An SSR functions more efficiently than an EMR, or electromechanical relay, due to its lack of moving components. SSRs operate silently, can switch settings at a faster rate, and have a much longer lifespan. This feature is especially helpful to industries that require frequent switching while also maintaining reliability.

If you are seeking solid state relays for your business’s automation processes, OMCH provides flexible solutions alongside durable performance for industrial systems. Their wide selection of SSRS ensures the longevity and relief clients need for their automation requirements.

Key Advantages for Industrial Use

Robotics, HVAC, and manufacturing companies can greatly benefit from adding SSRs to their systems, allowing them to implement more advanced technologies within their businesses. These advantages coincide with the greater goals of B2B companies focusing on more complex energy systems.

Durability and Reliability

Without mechanical contacts, SSRs are practically immune to wear and tear, which significantly increases their service life. This makes SSRs ideal for applications that require continuous or rapid switching.

Efficiency and Speed

Solid state relays have the ability to turn on and off in less than a millisecond. These devices are perfect for time-sensitive operations automation machinery, greatly influencing the efficiency and accuracy of the machinery.

Silent Operation

Unlike the EMRs that produce a clicking sound while switching, SSRs operate without a sound. Though it is not a functional requirement in all industrial environments, it may serve practical purposes in places such as laboratories or cleanrooms where noise minimization forms crucial criteria.

Vibration and Shock Resistance

With zero moving parts, SSRs are less prone to failure owing to external shocks or vibrations from physical stress. This is common on manufacturing floors and mobile systems.

Improved Reliability in Harsh Environments

Solid state relays tolerate a dustier environment, more humid, or even corrosive. This increases system uptime and decreases maintenance intervals. All of these factors are critical for industrial operations.

Reduced Maintenance Costs

Durability, silence, and no contact degradation over time SSRs need less replacements and inspections. This reduces the Total Cost of Ownership (TCO) for businesses insuring SSRs with their infrastructure.

Where Are Solid State Relays Commonly Used?

Multiple industries relying on SSRs depend on their versatility for diverse operational contexts making them useful for B2B companies.

Industrial Heating Systems

For ovens, plastic molding machines, and even packaging machinery, solid state relays are used to control their heaters. SSR precision switching maintains temperature control without mechanical wear and tear on the system.

Motor Control Systems

Even though SSR’s issues concerning heat dissipation are prevalent in large motors, they work extremely well in small motors such as pumps and fans. Small motors that use SSRs require seamless start and stop functionality.

Lighting Control

In industrial and commercial lighting systems, SSRs come with the ability of remote operation and automating lighting across office complexes, production lines or warehouses. SSRs also provide dependable switching in circuits that have lighting with high frequency.

HVAC and Refrigeration

For the blowers and valves of HVAC systems, SSRs help with controlling the compressors. With these controls, low level of sounds and high depends on the situation. Hence, SSR reliability for these statements is a useful benefit.

CNC and Automation Machinery

For programmable logic control machines as well as robotics, reliable apparatus SSR signal switching helps accomplish smooth operation control. Compact form factor SSR provides room for modern equipment integration.

Renewable Energy Systems

Power control systems and inverters alongside SSRs are greatly used in photovoltaic and wind systems where it’s essential to have high switching frequency and durability.

OMCH has industrial-class SSRs for these applications because of their small size, excellent thermal properties, and high isolation voltage. B2B automation integrators often select OMCH because of their reliability and global supply chain.

Important Factors When Choosing SSRs

System engineers and procurement teams put significant effort into finding the right SSR selection for their needs, and the right one requires considering several important parameters.

Type Of Load And Voltage

Make sure the SSR is configured to the voltage and current rating of your specific load (AC or DC). SSRs that are over or under rated will not work effectively or worst burn out.

Heat Dissipation Changes

Since SSRs are contactless, they do generate some heat. The extent of the load and the environment that SR is operated in must dictate the use of heatsinks and cooling fans.

Switching Type

Different SSRs are compatible with the zero-crossing and random turn on switching types. Even with Turn on random SSRs, zero crossing ones are quieter and greatly work with resistive loads such as heaters. These are more suited to inductive loads such as motors.

Control Voltage

Remember to confirm the control voltage matches the output from your output side control system. Most SSRs have a set range that is monitored, for example, 3 to 32 volt DC. But as with most devices, stress free operation will always be guaranteed if checked for compatibility.

Isolation and Safety Parameters

Always make sure that the SSR has the requisite safety and electric isolation features. Increased isolation voltage ratings provide more protection in industrial circuits.

Size and Mounting

SSRs are available in panel-mount, PCB-mount, or DIN-rail configurations. Choose a form factor that meets your space and installation requirements.

To examine the full range of solid state relays configurations suitable for B2B industries, visit the OMCH https://www.omchsmps.com/es/categoria-producto/ssr-relay/ .

The Evolution of SSR in Industrial Automation

As industries are digitized and automated, the use of solid state relays in power switching systems will take a more central position. The development of B2B SSR technology is opening new avenues along with:

- Smart SSRs offering diagnostic feedback

- Remote monitoring via IoT integration

- Modular, compact designs for easy scaling

- New materials for better thermal management

- Meeting Industry 4.0 requirements

OMCH is one of the providers who are first in these innovations. He has advanced SSRs tailored to modern requirements. B2B clients are enabled to strengthen the automation infrastructure because of focused industrial quality, efficiency, and engineering support.

Conclusion

For B2B companies aiming to improve the dependability, responsiveness, and lifespan of their industrial systems, solid state relays represent a worthwhile expenditure. SSRs greatly outperform electromechanical relays in performance supremacy, from heating control to automation machinery.

While you might be a systems integrator or an industrial buyer, partnering with a trusted vendor such as OMCH gives you access to competitively priced, SSRs of unmatched quality, tailored for diverse applications. SSRs will continue to be a primary component of intelligent industrial systems as these components become increasingly more in demand.